Company Introduction

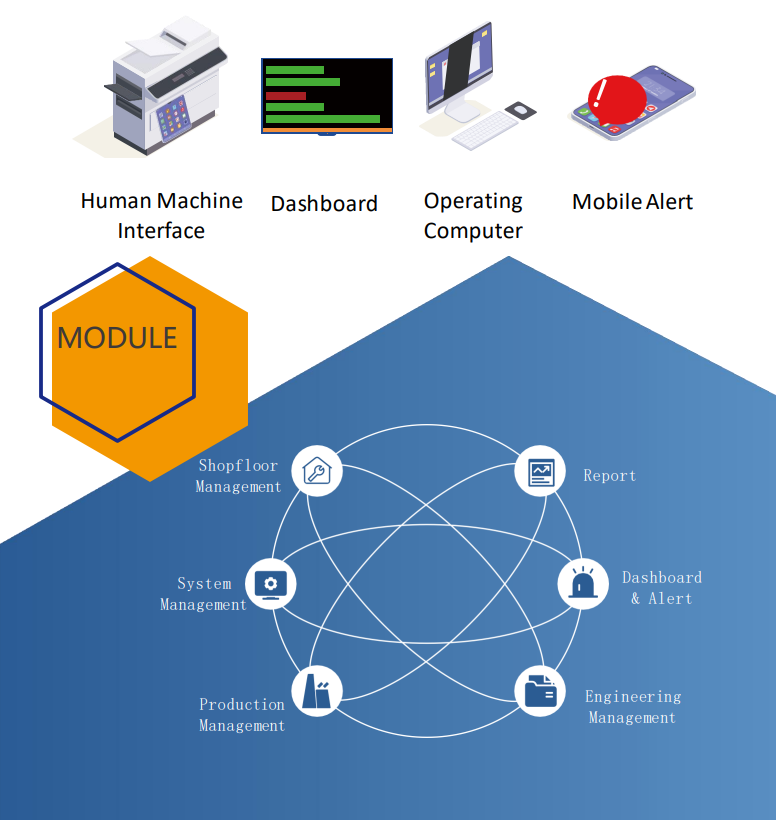

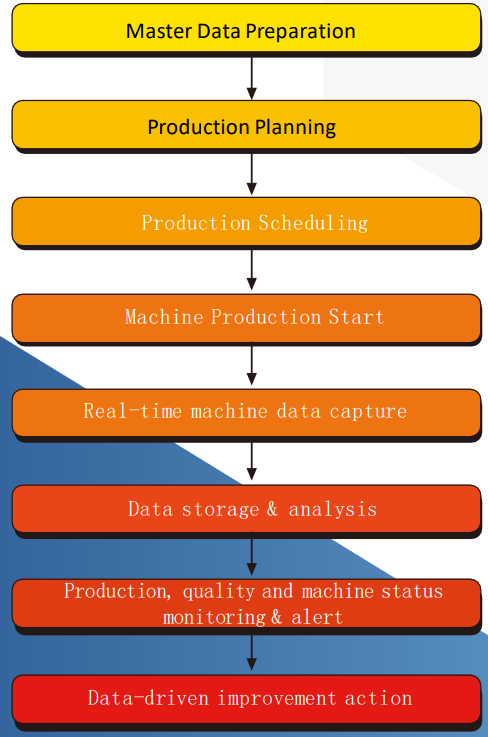

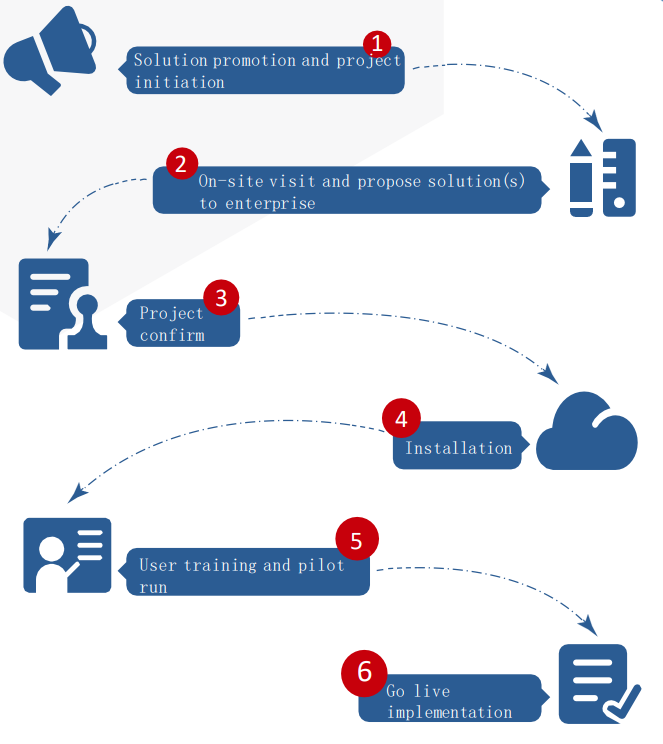

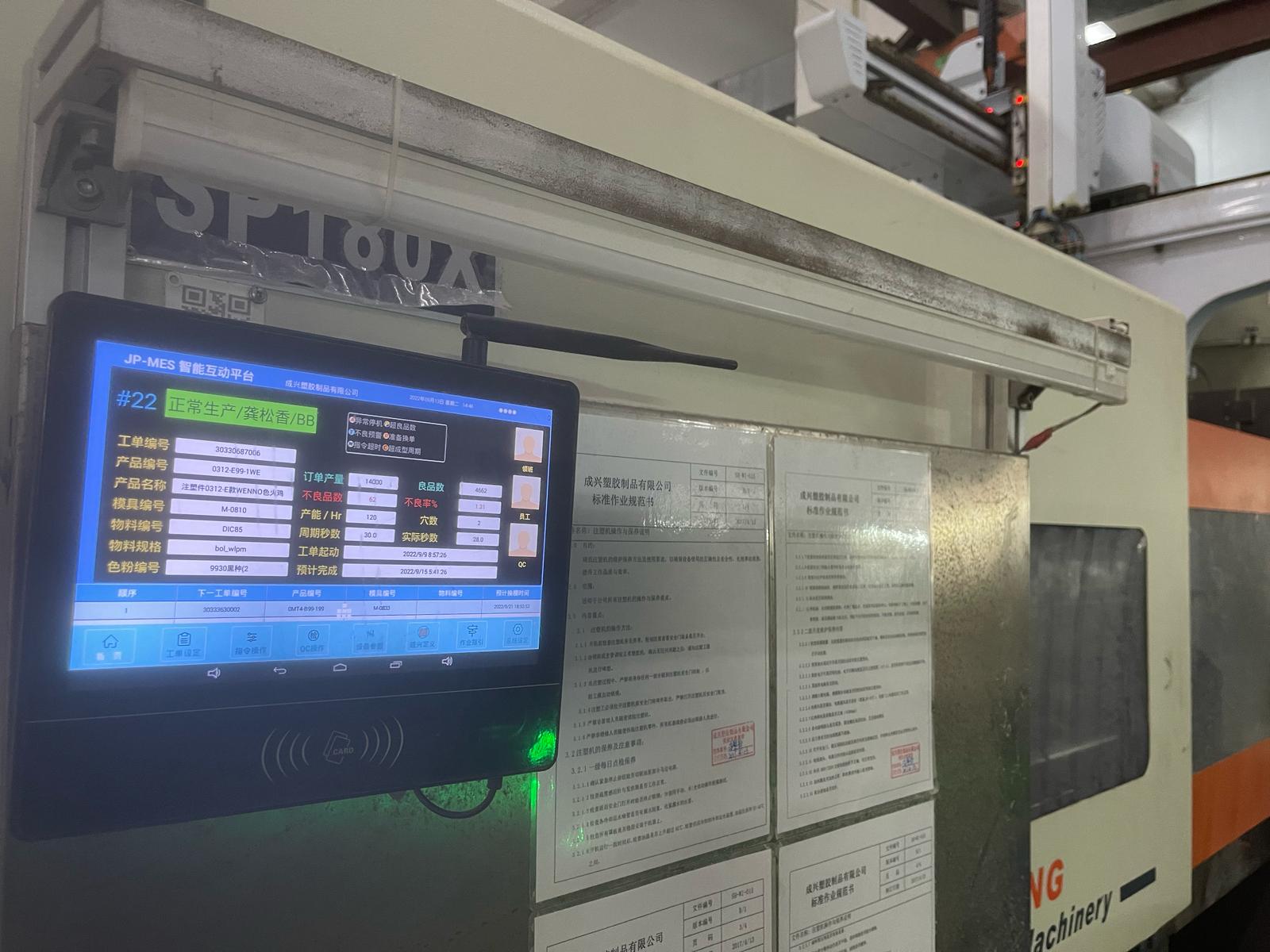

TUNG HING MANAGEMENT COMPANY LIMITED specializes in creating digital management solutions, utilizing technology to help enterprises optimize management processes and make production and product development intelligent. The company uses visual production management systems to help enterprises improve production efficiency, achieve intelligent and professional production management, and realize Industry 4.0 smart manufacturing! Through 3D printing combined with various surface treatments, product development solutions are further optimized! The company mainly provides visual management systems + product design management solutions, where the visual management systems include various forms of data collection, MES solutions, robotic arm visual inspection, programming software, etc.; product design management solutions include 3D printers and more.

Our company adheres to the business philosophy of customer first and service first, with excellent service quality, professional technical capabilities, and a skilled service team to ensure customers thrive in the information age. With the spirit of stability, development, loyalty, efficiency, unity, and innovation, respecting talent and emphasizing technology, we enable customers to enjoy the latest achievements in information technology while continuously obtaining maximum benefits. Our company has achieved brilliant results in various enterprise fields, completed numerous large-scale implementation solutions, and is willing to become your most trustworthy long-term partner.

- Pursue flexible and rapid production efficiency improvement

- Beneficial for product quality control

- Suitable for industrial production and manufacturing

- Future implementation of automated intelligent equipment integration